Oldindan isitish sensorli ekranli BGA qayta ishlash mashinasi

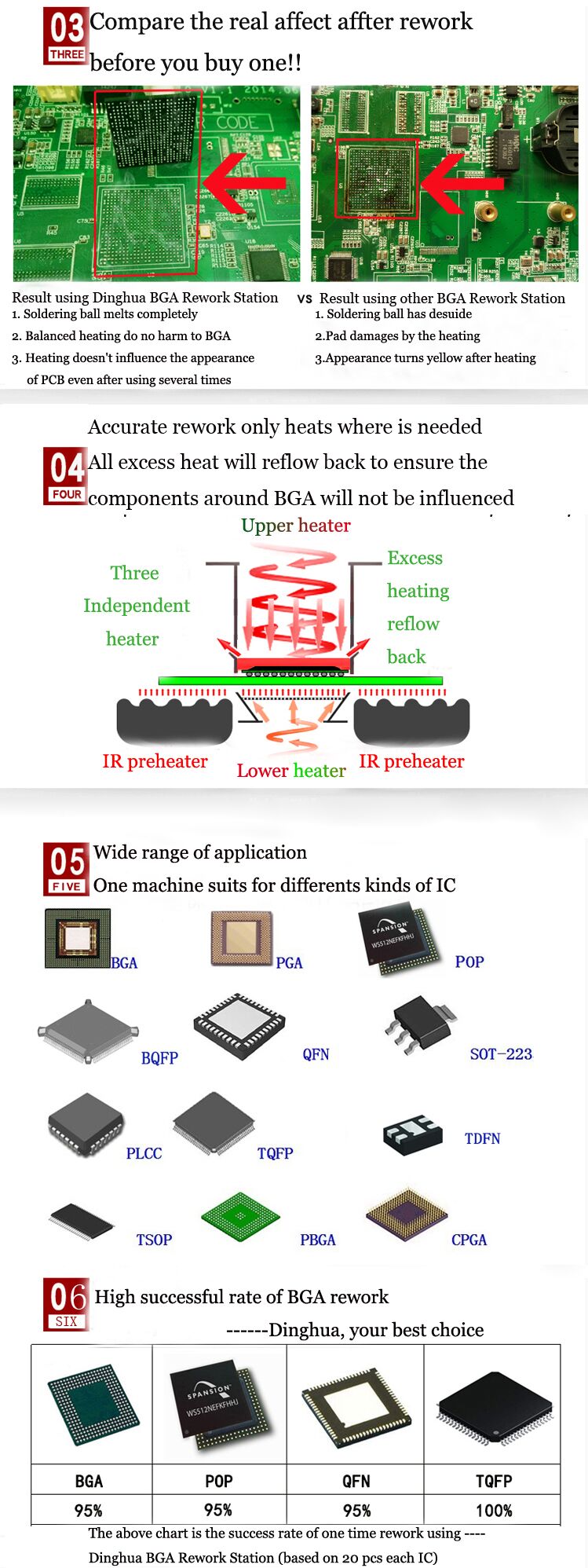

Bu yaqin atrofdagi ulagichlar va boshqa plastik qismlarga zarar bermasdan smartfonlardagi kichik komponentlarni almashtirish uchun ideal.

Ta'rif

Oldindan isitish sensorli ekranli BGA qayta ishlash mashinasi

1. Oldindan isitish sensorli ekranli BGA qayta ishlash mashinasining mahsulot xususiyatlari

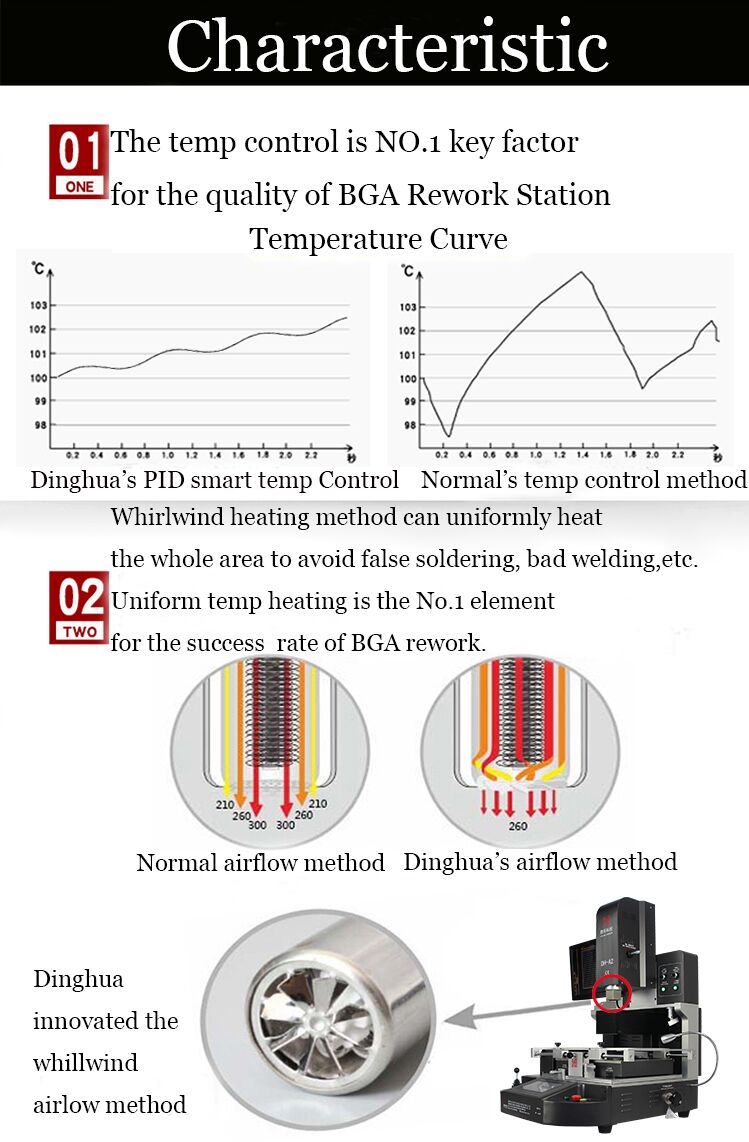

Yuqori va pastki haroratli hududlar mustaqil ravishda isitiladi, o'zaro oqim fanati tenglikni himoya qilish uchun tez soviydi

payvandlash paytida deformatsiya.

2. PCB ning katta termal quvvati yoki boshqa yuqori haroratli va qo'rg'oshinsiz payvandlash talablari uchun hammasi bo'lishi mumkin

oson ishlov beriladi.

3. Pre-heater monitoringi operatorga isitish moslamasi tayyor bo'lmaganda profilni ishga tushirishni oldini oladi.

4. Pre-heater tizimdan foydalanilmayotganda o'chirilishi yoki SetBack-ga qo'yilishi mumkin.

Vakuumli pik komponentlarni qulay joylashtirish uchun teta sozlamalarini o'rnatdi.

5. BGA olib tashlash va lehimdan keyin ovozli signal funksiyasi mavjud.

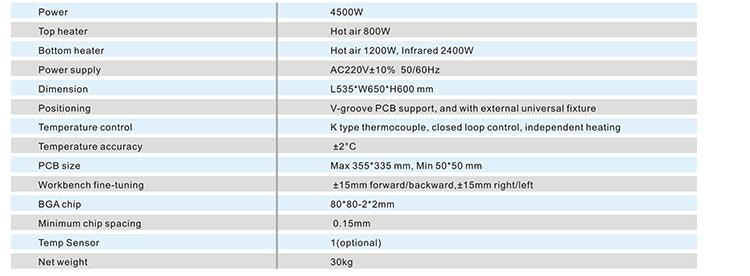

3.BGA qayta ishlovchi sensorli ekranni oldindan qizdirish mashinasining spetsifikatsiyasi

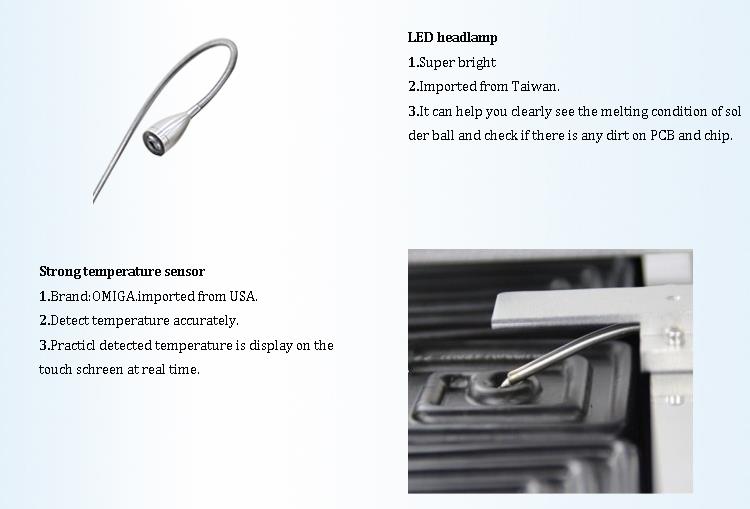

4. Sensorli ekranni oldindan qizdirish BGA qayta ishlash mashinasining tafsilotlari

1. HD sensorli ekran interfeysi;

2.Three mustaqil isitgichlar (issiq havo va infraqizil);

3. Vakuumli qalam;

4. LED fara.

5.Nega bizning old isitish sensorli ekranli BGA qayta ishlash mashinasini tanlaysiz?

6.BGA qayta ishlovchi sensorli ekranni oldindan qizdirish sertifikati

7. Oldindan isitiladigan sensorli ekranli BGA qayta ishlash mashinasini qadoqlash va jo'natish

8. Tegishli bilimlar

SMT ning ikki tomonlama aralash jarayoni

A: incoming inspection => PCB's B-side patch glue => patch => curing => flap => A-side PCB plug => wave soldering =>

cleaning => test =>qayta ishlash

Avval joylashtirishdan keyin, diskret komponentlardan ko'ra SMD komponentlari uchun mos keladi

B: incoming inspection => PCB A-side insert (pinning) => flap => PCB B-side spot adhesive => patch => curing => flap =>

wave soldering => cleaning => Test =>Qayta ishlash Qo'shishdan keyin va o'rnatishdan keyin, ko'proq komponentlarni ajratish uchun mos

SMD komponentlariga qaraganda

C: incoming material inspection => PCB's A surface silk screen solder paste => patch =>

drying => reflow soldering => plug-in, pin bending => flap => PCB B surface patch glue => Patch => Curing => Flap =>

Wave Soldering => Cleaning => Detection =>Qayta ishlash A sirt aralashtirilgan, B sirt o'rnatish. ?

D: incoming inspection => PCB's B side spot adhesive => patch => curing => flap =>PCB's A yon ipak ekranli lehim pastasi

=> patch => A side reflow => plug-in => B-side wave soldering => cleaning => test =>qayta ishlash A tomonini aralashtirish, B tomonini o'rnatish.

Birinchi SMD, qayta oqim, ishlab chiqarishdan keyingi, to'lqinli lehim

E: incoming inspection => PCB side B silk screen solder paste (point mount glue) => patch => drying (curing) => reflow soldering =>

flap => PCB side A silk screen solder paste => Patch => Drying = Reflow soldering 1 (local soldering can be used) => Plug-in =>

Wave soldering 2 (If there are few components, you can use manual soldering) => Cleaning => Test =>Yuzaki o'rnatishni qayta ishlash,

B yuzi aralash.